Exploring Aluminum Die Casting: A Look into the World of Die Casting in China

Introduction:

Aluminum die casting is a widely utilized manufacturing process that offers numerous advantages in terms of production efficiency and product quality. When it comes to die casting, China has emerged as a global powerhouse, leveraging its expertise and resources to become a leading hub for aluminum die casting. In this article, we will delve into the basics of aluminum die casting, highlight its benefits, and explore the thriving die casting industry in China.

Understanding Aluminum Die Casting:

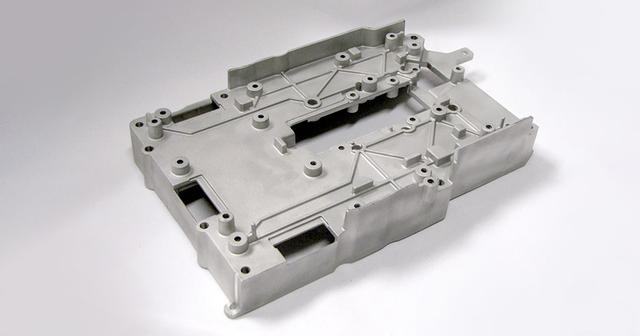

Aluminum die casting china is a process that involves injecting molten aluminum into a steel mold, also known as a die. This mold is precisely designed to shape the desired product. The molten aluminum rapidly cools and solidifies within the die, creating a high-quality, precisely dimensioned component. The process is known for its ability to produce complex, intricate, and lightweight parts with excellent surface finishes.

Advantages of Aluminum Die Casting:

- Design Flexibility: Aluminum die casting enables the production of intricate shapes and complex geometries that may not be feasible with other manufacturing processes. It allows for the integration of multiple features, such as threads, ribs, and bosses, reducing the need for additional assembly operations.

- Lightweight Strength: Aluminum is known for its exceptional strength-to-weight ratio. Die cast aluminum components offer lightweight characteristics without compromising on strength, making them suitable for applications that require high-performance and energy efficiency.

- Cost-Effective Production: Die casting provides an efficient means of mass production, as multiple parts can be produced in a single cycle. The high-speed production process coupled with minimal scrap material results in cost-effective manufacturing.

- Excellent Surface Finishes: Aluminum die casting delivers consistent and high-quality surface finishes, reducing the need for additional finishing operations. It produces components with smooth surfaces, intricate textures, and fine details, ready for use or further treatments like painting or powder coating.

Die Casting Industry in China:

China has rapidly evolved into a global leader in the die casting industry, with a robust infrastructure and a strong supply chain. The country benefits from a skilled workforce, advanced technology, and a vast network of manufacturers specializing in Aluminum die casting. These factors, coupled with competitive pricing, have made China an attractive destination for companies seeking high-quality die cast components.

The Chinese die casting industry offers a wide range of capabilities, from prototyping to large-scale production. Manufacturers in China possess expertise in various sectors, including automotive, aerospace, electronics, and consumer goods. With their focus on continuous improvement and technological advancements, Chinese die casting companies consistently deliver top-notch products to meet global demands.

Furthermore, the Chinese government’s support for the manufacturing sector has fostered innovation, encouraged research and development, and facilitated collaborations between companies and research institutions. This ecosystem has propelled the die casting industry in China to new heights, cementing its position as a reliable and competitive source for aluminum die cast components.

Conclusion:

Aluminum die casting is a versatile manufacturing process that offers numerous advantages, including design flexibility, lightweight strength, cost-effective production, and excellent surface finishes. China has emerged as a prominent player in the die casting industry, leveraging its capabilities, infrastructure, and skilled workforce to become a global hub for aluminum die casting. With its commitment to innovation and high-quality production, the die casting industry in China continues to thrive, meeting the diverse needs of industries worldwide.